Permeability of oil-gas Reservoir Rock

Permeability of Petroleum Reservoir Rock

In addition to being porous, a

reservoir rock must be permeable—that is, it must allow fluids

to flow through its pore network at practical rates under

reasonable pressure differentials. Permeability is defined as:

1.

The

ability of a formation to transmit fluids

2.

The

ability of rocks to allow the circulation of fluids contained in their

pores.

3.

The

ability of the rock to allow a fluid with which it is saturated to flow through its pores.

Permeability is a measure of the

ease with which the fluid flows in the porous medium. Figure 4.1

represents a schematic showing the difference between low and high permeability

rocks in a reservoir. The permeability of a rock measured when it is 100%

saturated with a single phase (water, oil, or gas) is often called “single-phase

permeability”, “absolute permeability,” or just “permeability”.

If there are two fluids flowing in a rock, then it relates to another concept

known as “relative permeability”.

Permeability is part of RCAL and is

considered as a flow or transport property that helps in understanding the flow

in the reservoir. The concept of permeability was first introduced by French

civil engineer Henry Darcy in 1856 when he performed an experiment on sand

filtrates and analysed the concept of permeability. Darcy’s law for a single

phase (liquid) is expressed as:

Where q - is the flow rate [m3/s],

k - is the permeability [m2], A - is the core cross-sectional area

perpendicular to the flow [m2], L is the length of the core [m], dP

is the pressure difference across the core [Pa or N/m2], and µ is

the viscosity of the injected fluid [Pa.s or N/m2.s].

This equation is the linear form of

Darcy’s law for incompressible fluid, which is discussed further in the

following sections.

Applications of Permeability

Permeability is a parameter that

describes the flow in porous media. From Darcy’s law, we can estimate the

production flow rate from the reservoir to the surface. This can be done by

determining the permeability of the reservoir through laboratory experiments on

core samples extracted from the same reservoir, as well as determining all the

parameters associated with Darcy’s law.

|

Figure 4.1: Schematic showing the

cross section at the micro-scale of (a) a lower permeability rock and (b) a

higher permeability rock. The fluid flow is much easier in rock (b) compared to

rock (a). |

Validity of Darcy’s Law for Single-Phase Permeability

Darcy’s law for single-phase flow is

valid under some conditions, which include:

The core sample used needs to be

100% saturated with a single phase (water, oil, or gas). If the system consists

of more than one fluid, then we need to consider relative permeability.

The flow has to be laminar. Flow can

be characterized as either laminar or turbulent. Laminar flow is defined as the

“slow,” uniform flow while turbulent flow is defined as the “fast,” chaotic

flow (Figure 4.2). In

order to determine whether the flow is laminar or turbulent, a dimensionless number

is used, known as the Reynolds number. This number is obtained from the

following equation:

Re=ρvD/μ

where Re - is the Reynolds number

[dimensionless], ρ - is the density of the fluid [kg/m3], v - is the

velocity of the fluid [m/s], D - is the pipe diameter [m], and µ - is the

viscosity of the fluid [Pa.s].

A flow with Reynolds number of 2100

or less is considered laminar.

This equation is mainly used in pipes as they

have a fixed diameter; however, for a porous medium, an average grain diameter

is used. Since it is difficult to compute Reynolds number in porous media, another

technique is used to determine whether the flow is laminar or turbulent. This technique is used when measuring

permeability in the laboratory and will be discussed in the following sections.

It is important to mention that in a reservoir; the flow is generally laminar.

The flow has to be steady-state

flow. Steady-state flow means that whatever enters the system leaves the system,

or that there is no volumetric change over time. This is true for fluid flow in

core samples if the same amount of fluid enters and leaves the system over a certain

period. If the flow is unsteady-state, then Darcy’s law is invalid.

Figure 4.2: Schematic showing the

two different types of flow: (a) laminar flow (a flow that is uniform, smooth,

and occurs at low flow rates) and (b) turbulent flow (a flow that is chaotic

and occurs at high flow rates compared to laminar flow). |

The flow in porous media has to be laminar in order for Darcy’s law

to be valid.

Darcy’s Law Under Different Boundary Conditions

In this section, we will derive

Darcy’s law for different boundary conditions by starting from the differential

form of Darcy’s law:

where q is the flow rate [m3/s], k is the permeability [m2], A is the cross-sectional area perpendicular to

flow [m2], dx is the change

in length [m], dP is the pressure

difference across the core [Pa], and µ is

the viscosity of the injected fluid [Pa.s].

Fluids can be either compressible or

incompressible. “Fluid” is a term that refers to liquids and gases.

Compressible fluids are fluids that change volume due to a change in pressure,

such as gases. Liquids, on the other hand, are considered incompressible

because their volumes change negligibly with a change in pressure. An example

of compressible fluids in real-life applications is scuba tanks, where air is

compressed inside the tank. The actual volume of the compressed air in the

tank, under atmospheric pressure, is much larger than the actual volume of the

tank itself. However, if we wish to fill the same tank with water (which is an

almost incompressible fluid), the volume of water that fills the tank will approximately

be the same inside and outside the tank. When we consider flow in porous media,

we need to consider whether the flow is compressible or incompressible, as this

will change the governing equations. In addition, we need to consider whether

the flow is linear in Cartesian coordinates (most laboratory experiments) or

radial coordinates (reservoir conditions).

Case 1: Linear solution of Darcy’s Law for incompressible fluid

Let us assume we have the system shown in Figure 4.3, and we inject it with an incompressible fluid such as water. Based on the system, we know that the length is L, the inlet pressure is P1, and the outlet pressure is P2. In order for the flow to occur from the inlet to outlet, P1 needs to be greater than P2, because fluid flows from high pressure to low pressure. This is analogous to the movement of most of the other flows, such as the flow of electrical charges from high to low voltage, and heat transfer from high to low temperature. Our homes also have a real-life example of such flows. In a vacuum cleaner, for the particles to flow to the dust collector, a pressure lower than the atmospheric pressure is required inside the appliance. The vacuum cleaner achieves this by creating a partial vacuum inside the machine for the particles or dust to flow towards it.

Darcy’s law is usually written with

a negative sign. This is because dP = P2 – P1 and since P2

is smaller than P1, a negative sign will make the overall equation

positive. For simplicity, we will use the following differential form of

Darcy’s law:

Where dP = P1 – P2

and P1 > P2.

Now, we can rearrange the equation

to obtain:

Taking the integral with the

boundary limits as shown in Figure 4.3:

Then, the equation becomes:

Finally, we divide both sides by L:

Equation is the final form of

Darcy’s law for an incompressible linear system.

|

Figure 4.3: Schematic showing a

cylindrical core sample used for permeability measurement, where a cross

section is taken to display the boundary limits of the linear system. |

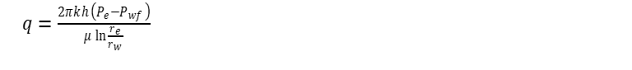

Radial solution of Darcy’s Law for incompressible fluid

In this case, the only difference is that the flow occurs in a

radial manner as opposed to linear. This flow is more representative of a

reservoir. One of the changes is that the area perpendicular to the flow is the

circumference of the circle (2πr) multiplied by the thickness of the reservoir

(h) (in contrast to πr2 in the linear flow for a cylindrical-shaped

object). The second change is that instead of the flow varying in the

x-coordinate, it will vary in the r-coordinate and thus instead of having

dP/dx, we will have dP/dr. Figure 4.4 shows the radial system of

the reservoir.

We start with the differential form of Darcy’s law and substitute the area perpendicular to flow, which is the circumference of

the circle, and change the coordinates from linear to radial. The equation

becomes:

q=(2kπrh/μ)*(dP/dr)

Then, we rearrange the equation to obtain:

q (dr/r)=(2πkh/μ)*dP

Now, we take the integral with the boundary limits in agreement

with Figure 4.4, thus obtaining:

where re is the reservoir’s outer radius [ft], rw

is the well radius [ft], Pe is the reservoir’s outer pressure

[psia], and Pwf is the wellbore flowing pressure [psia].

Then, we integrate the equation with the given boundary condition to obtain:

This is the final form of Darcy’s

law for incompressible radial system.

Dealing with gases is different from

liquids as gases are compressible fluids. Hence, we need to account for the

change in volume when deriving the equation.

In addition, equations for Darcy’s

law for different systems can also be modified to account for the gravity term

in vertical systems. Nevertheless, these equations are rarely used in petroleum

engineering, as the flow in the reservoir and in laboratory experiments is

mainly horizontal.

Unit Systems

When using Darcy’s law, three main unit systems can be used to find

permeability. These units are explained in Table 4.1. It is

important to note that since permeability values are very small in m2,

a unit of Darcy [D] or milli Darcy [mD] is used, named in honor of Henry Darcy.

Moreover, the unit bbl/d in the table indicates barrel (bbl) per day (d), which

is a standard unit to quantify volume in the oilfield units.

|

Table 4.1: Summary of different units

used when dealing with permeability. |

|||

|

Parameter |

SI Units |

Darcy Units |

Oilfield Units |

|

q (flow rate) |

[m3/s] |

[cm3/s] or [cc/s] |

[bbl/d] |

|

L (length) |

[m] |

[cm] |

[ft] |

|

A (area) |

[m2] |

[cm2] |

[ft2] |

|

h (thickness) |

[m] |

[cm] |

[ft] |

|

r (radius) |

[m] |

[cm] |

[ft] |

|

P (pressure) |

[Pa] |

[atm] |

[psia] |

|

k (permeability) |

[m2] |

[D] |

[mD] |

|

µ (viscosity) |

[Pa.s] |

[cP] |

[cP] |

By rearranging Equation, the following equation is obtained,

which can be used to find permeability in SI or Darcy units:

However, for oilfield units, this equation is multiplied by a

conversion factor for linear flow:

and similarly, for radial flow:

Laboratory Measurements of Absolute Permeability

Liquid Permeability

The permeability of core samples is measured using either liquid or

gas. The procedure and the governing equation are different for each case.

Before we start measuring the

permeability of a core sample, we first need to measure its dimensions (length

and diameter) as length and area are part of Darcy’s law. Secondly, we insert

the core sample in a core holder as shown in Figure 4.5. A common

procedure is to vacuum the core using a vacuum pump prior to injecting any

liquid. This is to remove any air from the system and to ensure the flow of

only one phase. Then, a liquid (in this case water) is injected at a specific

rate using a pump. Before injecting the water, we need to ensure that a confining

pressure, similar to the overburden pressure that is squeezing the core sample

from all the sides, is applied. This is done in order to guarantee that the

water is only going through the core sample and not bypassing it as that will

generate errors in the measurement. A general rule of thumb is to apply a

confining pressure (the oil pressure in Figure 4.5) that is at

least 1.5 times higher than the water injection pressure. When water is

injected at a constant flow rate, a wait time is required in order to achieve a

steady- state flow where the inlet and outlet pressures become constant and do

not fluctuate. After the steady-state flow is achieved, we record the flow

rate, inlet pressure, and outlet pressures. We then move on to a new flow rate

and follow the same procedure. After recording a few data points, we can plot

the data in order to find the permeability of the core sample.

If we rearrange Darcy’s law for the

liquid phase, it becomes:

This equation is in the linear form

y = mx+b, where y is the dependent variable (q/A), x is the independent

variable (dP/L), m is the slope (k/µ), and b is the y-intercept. The

y-intercept in this case is 0 since the curve goes through the origin.

If we plot this figure with our

data, a figure similar to Figure 4.6 will be generated. The slope

of that figure will be equivalent to the permeability divided by the viscosity.

In order to obtain the permeability, the slope needs to be multiplied by the

viscosity.

|

Figure 4.5: Schematic showing the

experimental set-up to measure the liquid permeability of a core sample. In

this system, we inject water through the core sample and use oil to apply a

confining pressure, which should be higher than the water injection pressure. |

Gas Permeability

Dealing with gas is different

because gas is compressible as opposed to liquids. Thus, the governing

equations will be different as well to account for this change in volume.

Measuring the gas permeability has advantages over measuring liquid

permeability. The measurements for gas take less time than those for liquid, and

gas does not wet the core, which means the core can be reused for further

analyses. The disadvantage is that gas permeability requires correction as it

tends to be overestimated compared to liquid permeability. Figure 4.7

shows the typical experimental set-up used to measure gas permeability. Since

it is difficult to control the gas flow rate, the core holder is attached to a

gas cylinder, and a metering valve is used to vary the flow rate. There is a

flow meter at the end of the core to measure the flow rate at atmospheric

conditions. The simplest way to derive the equation for the gas permeability is

to take the average pressure across the core:

where P is the average pressure

across the core [atm].

We use the average pressure because

the flow rate varies across the core and an average value would be more

representative of the flow in the core. We can use Boyle’s law as shown in

Equation We divide both volumes by time (t) in order to convert it to

flow rate. Thus, the equation becomes:

We compare the average flow rate

across the core to the flow rate at atmospheric conditions; since the

atmospheric pressure is 1 atm, it can be eliminated from the equation.

If we rearrange Equation, it

becomes:

Now, we substitute this equation in

Equation:

Next, we can move to the other side

of the equation and substitute Equation in it to obtain:

Then, by rearranging the equation

and factorizing it, we obtain:

For simplicity, Pa is substituted as

1 atm when using Darcy’s units and thus the equation becomes:

Similar to liquid permeability, we

can rearrange the equation to find the gas permeability across the core after

acquiring several data points (Figure 4.8). When dealing with

gases, it is more common to reach a higher flow rate than liquids, because

gases have lower viscosity that can result in turbulent flow, making Darcy’s

law invalid. This can be seen from the plot. A laminar flow, which might also

be referred to as “Darcy’s flow,” will follow the slope from the origin and,

once the slope deviates, enter the turbulent flow regime or “non-Darcy’s flow”.

The data that falls in the turbulent flow regime has to be omitted from the

analysis.

When comparing gas permeability to

liquid permeability, gas permeability tends to be higher than the latter. This

is due to a gas slippage at the pore walls known as the Klinkenberg effect.

This gas slip makes the permeability higher than what it should be; therefore,

it is not representative of the actual value. Fortunately, this can be

corrected by computing the gas permeability (kg) at every

data point and then plotting it

against the inverse of P, as shown in Figure 4.9. The y-intercept

of this line is the equivalent liquid permeability (kL). The x-axis

of the plot is the inverse of P, so

a zero value of x represents infinite pressure. At infinite pressure, gas can

be considered to behave as a liquid. One factor that affects this slippage is

gas molecular weight. As the gas molecular weight increases, the slippage

decreases since gas becomes heavier and closer to liquid. This effect is shown

in Figure 4.10.

|

Figure 4.7: Schematic showing the

experimental set-up for measuring the gas permeability of a core sample. |

Flow in Layered Systems

The objective of understanding the

flow in a layered system is to find the average permeability across that system

with beddings of different permeability. The concept is similar to an

electrical circuit; the average permeability will vary if the flow is in

parallel or series to the beddings in the system. In addition, it could also

vary if the flow is linear or radial. We will now examine each case

individually.

Case 1: Linear Flow in Parallel

Let us assume a system similar to Figure

4.11 which has three beddings with different permeabilities parallel to

each other, and we try to find the average permeability in that system. First,

we can see a constant pressure difference across the system; however, the flow

rate will be different across each layer as the flow rate is a function of the

permeability of that bedding. Therefore, we can say that the total flow rate

(q) is equal to:

q = q1 + q2 + q3

We also know that the summation of

the thickness of each layer is equal to the total thickness of the system:

h = h1

+ h2 + h3

The total flow rate of the system is equal to:

Then, we substitute for the flow

rate from Darcy’s law in Equation:

Now, we can factor the common

parameters in the equation which will lead to:

kh= k1h1 + k2h2 + k3h3

Finally, we can generalize the

equation to obtain:

This equation can be used to

estimate the average permeability in a linear system where the beddings are

parallel to each other.

|

Figure 4.11: Schematic showing a

linear system with parallel beddings of different permeabilities. |

Case 2: Linear Flow in Series

Let us assume a system shown in Figure 4.14 which has

three beddings in series with each other; each bedding has a different

permeability. Here, the same flow rate passes through all these rocks:

q = q1 = q2 = q3

However, the pressure across each rock is different, as shown in Figure

4.14 and explained in Figure 4.15. It can be said that:

P1−P2 = ∆P1 +∆P2 +∆P3

Furthermore, the total length is composed of the length of each

rock:

L = L1 + L2 + L3

We know that the flow rate across the entire system is equal to:

Now, we will substitute Darcy’s law

in Equation by making ∆P of each respective equation as the subject to

obtain:

We can now remove the common parameters and the equation becomes:

We can also represent this equation

in the following general form:

This equation can be used to estimate

the average permeability in a linear system, where the beddings are in series

with each other.

|

Figure 4.12: Schematic showing a

linear system with beddings of different permeabilities in series. |

|

Figure 4.13: Schematic showing the

pressure profile across a composite system with beddings in series with each

other. |

Radial Flow in Parallel

The flow in parallel systems in

radial orientation (Figure 4.14) is similar to that in linear

orientation, as will be proven below.

First, the overall flow rate is the

summation of all the flow rates across the layers, and the

total thickness is the summation of all the thicknesses across all the layers.

The total flow rate for this system

is equivalent to:

Now, if we substitute each flow rate

in each layer in Equation, we will have:

We can now factor the common

parameters to obtain:

The form is indeed the same as the

linear system and can also be represented in the same general form:

This equation can be used to

estimate average permeability in a radial system where the beddings are parallel

to each other.

|

Figure 4.14: Schematic showing a

radial system with beddings of different permeabilities in parallel. |

Radial Flow in Series

The flow in series for a radial

system is shown in Figure 4.15. We know that the flow rate across

the layers is the same; however, the pressure

difference in each layer is different as shown in Equation. The flow rate

in a radial system is expressed in Equation.

By substituting Darcy’s law in

Equation and making ∆P of each respective equation as the subject, we

obtain:

Then, we eliminate the common

parameters and rearrange the equation to obtain this generic form:

where r(i+1) represents

the outer radius of layer i and ri represents the inner layer.

This equation can be used to estimate the

average permeability in a radial system where the beddings are in series with

each other.

|

Figure

4.15: Schematic showing a radial system with beddings of different

permeabilities in series. |

The Porosity-Permeability Relationships

The relationship between a

formation’s permeability and porosity depends on the rock type, and

particularly the specific rock formation (Figure 4-15).

As a broad generalization, the

logarithm of the permeability is approximately linear with porosity for most

rock types. However, the precise relationship is found only through the direct

measurement of representative formation rock core samples in the laboratory, or

by drill stem test interpretation.

|

Figure

4-16: Generic permeability/porosity relationships |

A number of researchers have

developed theoretical relationships between the permeability and porosity by considering

some textural features such as the size, shape, and distribution of pore

channels in the rock. Notable among these are Kozeny (1937) and Carman (1927),

with modifications by Costa (2006), who have developed relationships between

porosity and permeability, such as:

Where k is permeability, ϕ is

porosity, C is the Kozeny constant, and As is internal surface area

per unit bulk volume

For fractured rocks, generalized

formulas have been developed that relate the permeability to a function of the

fracture width.

In many reservoirs, the permeability

is anisotropic—the magnitude of permeability varies as a function of the

direction and degree of grain

alignment. For example, the fluvial deposition of sediments

tends to align grains in the direction of the river’s flow along their long

axis, thus increasing the permeability in that direction. In almost all bedded

reservoirs, the vertical permeability of the rock will be less than the

horizontal permeability.

There are a number of factors that can affect the

porosity-permeability relationship, including:

1.

The size and shape of the pores.

2.

The connectivity of the pores.

3.

The tortuosity of the pore space.

4.

The fluid viscosity.

5.

The fluid density.

6.

The acceleration due to gravity.

The porosity-permeability relationship is an important

concept in the study of porous media. It is used to design and optimize fluid

flow systems, such as oil and gas wells. The relationship is also used to

characterize the properties of porous media, such as soils and rocks.

Effective and Relative

Permeabilities

Effective permeability and relative permeability are two important

concepts in petroleum engineering. They are used to describe the flow of fluids

in porous media, such as oil reservoirs.

Effective Permeability

The

permeability of a rock to a fluid phase (oil, gas, or water) in the presence of

other fluid phases. It is a measure of the ability of that phase to flow in the

presence of the others. The effective permeability of a fluid phase will

decrease as the saturation of that phase decreases. It is measured in Darcy’s

or millidarcys and is therefore the dimensional equivalent of absolute

permeability, hence:

ko =

effective permeability to oil, darcys or md

kw =

effective permeability to gas, darcy or md

kg =

effective permeability to gas, darcys or md

Individual

values of ko, kw, kg may vary from zero up to

the absolute value, k:

Effective

permeability is a function of:

1.

The

prevailing fluid saturation

2.

The

rock-wetting characteristics

3.

The

geometry of the pores of the rock.

The saturations, if known, should be

specified to completely define the conditions at which a given effective

permeability exists.

Unlike the

previously defined permeability, one now exists for each particular condition

of fluid saturation. Symbolically, the effective permeability of the medium to

oil is 60 percent when the fluid saturations are 60 percent oil, 13 percent

water, and 27 percent gas. The saturation succession given above, i.e., oil and

water, is always followed. The gas saturation is understood to be the

difference between the sum of oil and water saturations at 100 percent.

It is necessary

to generalize Darcy's law by introducing the concept of "effective

permeability" to describe the simultaneous flow of more than one fluid. In

the definition of effective permeability, each fluid phase is considered to be

completely independent of the other fluids in the flow network. The fluids are

considered immiscible, so Darcy's law can be applied to each individually.

In the same

manner when, porous medium is partly saturated with gas, then the flow rate of

gas defined by

Relative Permeability

It is the ratio

of the effective permeability of a fluid phase to the absolute permeability of

the rock. It is a dimensionless quantity that describes the relative ability of

a fluid phase to flow in the presence of the other phases. The relative

permeability of a fluid phase will decrease as the saturation of that phase

decreases. Thus, relative permeability can be expressed symbolically

Which are the

relative permeabilities to oil, water, and gas, respectively, when the medium

is saturated with 50 percent oil, 30 percent water, and 20 percent gas, and

what is the permeability at 100 percent saturation of one of the fluid phases.

Relative

permeabilities are influenced by the following factors:

Ø Temperature

Ø Viscous, capillary and gravitational forces

Ø Pore geometry

Since the effective permeabilities may range from zero to k,

the relative permeabilities may have any value between zero and one:

Another widely used parameter is the ratio of the effective (or

relative) permeabilities of water and oil, and gas and oil:

And

These ratios are dimensionless and may vary from zero to infinity.

Two phase flow behavior

Consider the two-phase flow behavior in Figure 4.17:

Water and oil completely occupy the pore space, ensuring that Sw+So=100%

at all times.

assumptions

Ø Rock is originally 100% saturated with oil.

Ø We introduce water into every pore simultaneously, and a water-wet equilibrium

is instantaneously established.

When water is

first introduced, it is adsorbed by the rock and held immobile both on the rock

surfaces and in the small corners around the points where different grains

converge. Region A shows this immobility to be present. But take note that it

basically stays at 1.0 over the same saturation range. As this process goes on,

the water saturation reaches a critical point (Swc) where water

starts to move around. Both water and oil are currently flowing; however, as

water saturation rises (and oil saturation falls), there are both increases and

declines, as seen in area B. When the oil saturation reaches a residual value

(SO), only water flows and the SW continues to climb. At

this point, the oil is no longer mobile. This is the lowest saturation to which

water injections can decrease oil.

If the oil

could be extracted in another way, the price would continue to rise until it

reached the value of one, as shown.

Many

researchers in this field have proposed generalized empirical equations to

relate kro and krw to Sw, Swi and Sor.

Of particular note are those cited in Honarpour, Koederitz and Harvey (1982),

Molina (1983), and Pirson, Boatman and Nettle (1964). A commonly used

approximation gives:

|

Figure 4.17 Typical two-phase flow behavior |

If a well is

completed above the transition zone where the reservoir is at irreducible water

saturation (krw = 0), then water will not be produced.

However, if a

well completion is contemplated in the transition zone, it is useful to know in

advance how much water cut may be expected. This can be calculated as follows:

Three-Phase Relative Permeability

Three phases

(water, oil, and gas) can flow simultaneously sometimes and in order to

characterize the flow in these cases, three-phase relative permeability is

introduced. The usage of three-phase relative permeability is minimal in the

petroleum industry when compared to two-phase relative permeability. In

addition, laboratory measurement of three-phase relative permeability is very

difficult to perform. Therefore, Stone came up with two models Stone I and

Stone II to estimate three-phase relative permeability from two-phase relative

permeability (oil/water and oil/gas); the details of the two models are not

discussed in this book and can be found elsewhere.

Three-phase

relative permeability is presented in ternary diagrams (Figure 4.18)

where each phase is placed in an apex with gradual decrease in saturation away

from the respective apex. The water, oil, and gas three-phase relative

permeabilities are shown in Figures 4.19–4.21, respectively.

This lecture has been uploaded to YouTube. To follow the video about the lecture on the permeability of reservoir rocks, please watch below or go to YouTube by clicking on the link here.

Comments