Gas-Lift Troubleshooting

Gas-Lift Troubleshooting: How to Diagnose Well Issues Before Calling a Rig

Gas-lift problems are usually associated with three areas: inlet, outlet, and downhole (Fig. 1).

|

| Fig. 1: The Gas-Lift System |

Inlet Problems

Choke sized too large.

Check for casing pressure at or above design operating pressure. This can cause reopening of upper-pressure valves and/or excessive gas usage. Approximate gas usages for various flow rates are included in Fig. 2.

Choke sized too small.

Check for reduced fluid production as a result of insufficient gas injection. This condition can sometimes prevent the well from unloading fully. The design gas:liquid ratio can often give an indication of the choke size to use as a starting point.

Low casing pressure.

This condition can occur because the choke is sized too small, it is plugged, or it is frozen up. Choke freezing can often be eliminated by continuous injection of methanol in the lift gas. A check of injected-gas volume will separate this case from low casing pressure based on a hole in the tubing or cutout valve. Verify the gauge readings to be sure the problem is real.

High casing pressure.

This condition can occur because the choke is too large. Check for excessive gas usage from the reopening of upper pressure valves. If high casing pressure is accompanied by low injectiongas volumes, the operating valve may be partially plugged or high tubing pressure may be reducing the differential between the tubing and casing.

If this is the case, remove the flowline choke or restriction. High casing pressure accompanying low injection-gas volumes may also be caused byhigher-than-anticipated temperatures raising the set pressures of pressure

operated valves.

Inaccurate gauges.

Inaccurate gauges can cause false indications of high or low casing pressures. Always verify the wellhead casing and tubing pressures with a calibrated gauge.

Check to ensure that the gas-lift line valve is fully open and that the casing choke is not too small, frozen, or plugged. Check to see if the available operating pressure is in the range required to open

the valves. Be sure that the gas volume is being delivered to the well.

Nearby wells, especially intermittent wells, may be robbing the system. Sometimes a higher-than-anticipated producing rate and the resulting higher temperature will cause the valve set pressure to increase, thereby restricting the gas input.

Excessive gas volume.

This condition can be caused by the casing choke sized too large or excessive casing pressure. Check to see if the casing pressure is above the design pressure, causing upper pressure valves to be opened. A tubing leak or cutout valve can also cause this symptom, but they will generally also cause a low casing pressure.

Intermitter problems.

Intermitter cycle time should be set to obtain the maximum fluid volume with a minimum number of cycles. Injection duration should then be adjusted to minimize tail gas. Avoid choking an intermitter unless absolutely necessary. For small gas-lift systems in which opening the intermitter drastically reduces the system pressure, it may be possible to reduce pressure fluctuation by placing a small choke in parallel dead

wells as volume chambers. Check to make sure that the intermitter has not stopped, whether it is a manual-wind or battery-operated model. Wells intermitting more than 200 BFPD should be evaluated for constant low application.

Less than one barrel per cycle is probably an indication that the well is being cycled too rapidly.

Outlet Problems

Valve restrictions.

Check to ensure that all valves at the tree and header are fully open or that an undersized valve is not in the line (1-in. valve in a 2-in. lowline). Other restrictions may result from a smashed or crimped lowline.

Check locations where the line crosses a road, which is where this situation is likely to occur.

High backpressure.

High backpressure can also result from parafin or scale buildup in the lowline. Hot-oiling the line will usually remove parafin; however, removal of scale may or may not be possible, depending on the type. Where high backpressure is caused by long lowlines, it may be possible to reduce the pressure by looping the lowline with an inactive line. The same would apply to cases in which the lowline ID is smaller than the tubing ID. Sometimes a partially opened check valve in the lowline can cause excessive backpressure. Common lowlines can cause excessive backpressure and should be avoided if possible. Check all possibilities, and remove as many restrictions from the system as possible.

Separator operating pressure.

The separator pressure should be maintained as low as possible for gas-lift wells.

Often a well may be lowing to a high or intermediate pressure system when it dies and is placed on gas lift. Make sure the well is switched to the lowest-pressure system available. Sometimes an undersized oriice plate in the meter, at the separator, will cause high backpressure.

Downhole Problems

Operating pressure valve by surface closing-pressure method.

A pressure-operated valve will pass gas until the casing pressure drops to the closing pressure of the valve. As a result, the operating valve can often be estimated by shutting off the input gas and observing the pressure at which the casing will hold. This pressure is the surface closing pressure of the operating valve, or the closing-pressure analysis. The opening-pressure analysis assumes the tubing pressure to be the same as the design value and at single-point injection. These assumptions limit the accuracy of this method because the tubing pressure at each valve is always varying, and multipoint injection may be occurring. This method can be useful when used in combination with other data to bracket the operating valve.

Well blowing dry gas.

For pressure valves, check to ensure that the casing pressure is not in excess of the design operating pressure, which causes operation from the upper valves. Using the procedure mentioned above, make sure that there are no holes in the tubing. If the upper valves are not being held open by excess casing pressure and no hole exists, then operation is probably from the bottom valve.

Additional verification can be obtained by checking the surface closing pressure as indicated above. When the well is equipped with fluid valves and a pressure valve on the bottom, blowing dry gas is a positive indication of operation from the bottom valve after the possibility of a hole in the tubing has been eliminated. Operation from the bottom valve usually indicates a lack of feed-in. Often it is advisable to tag bottom with wireline tools to determine whether the perforations have been covered by sand. When the well is equipped with a standing valve, check to ensure the standing valve is not stuck in the closed position.

Well will not take any input gas. Eliminate the possibility of a frozen input choke or a closed input gas valve by measuring the pressures upstream and downstream of the choke. Also, check for closed valves on the outlet side.

If fluid valves were run without a pressure valve on bottom, this condition is probably an indication that all the fluid has been lifted from the tubing and not enough remains to open the valves. Check for feed-in problems. If pressure valves were run, check to see if the well started producing above the design fluid rate because the higher rate may have caused the temperature to increase sufficiently to lock out the valves. If the temperature is the problem, the well will probably produce periodically and then stop. If this is not the problem, check to make sure that the valve set pressures are not too high for the available casing pressure.

Well flowing in heads.

Several causes can be responsible for this condition. With pressure valves, one cause is port sizes that are too large. This would be the case if a well initially designed for intermittent lift were placed on constant flow because of higher-than-anticipated fluid volumes. In this case, large tubing effects are involved and the well will lift until the fluid gradient is reduced below a value that will keep the valve open. This case can also occur because of temperature interference.

For example, if the well started producing at a higher-than-anticipated fluid rate, the temperature could increase, causing the valve set pressures to increase and locking them out. When the temperature cools sufficiently, the valves will open again, thus creating a condition in which the well would flow by heads. With tubing pressure having a high tubing effect on fluid-operated valves, heading can occur as a result of limited feed-in. The valves will not open until the proper fluid load has been obtained, thus creating a condition in which the well will intermit itself whenever adequate feed-in is achieved. Because an injection gas rate that is too high or too low can often cause a well to head, try tuning in the well.

Gas-lift operation stalls and will not unload. This typically occurs when the fluid column is heavier than the

available lift pressure. Applying injection-gas pressure to the top of the fluid column, usually with a jumper line, will often drive some of the fluid column back into the formation. This reduces the height of the fluid column being lifted and allows unloading with the available lift pressure. This procedure is called “rocking the well.” The check valves prevent this fluid from being displaced back into the casing. For fluid-operated valves, rocking the well in this fashion will often open an upper valve and permit the unloading operation to continue. Sometimes a well can be swabbed to allow unloading to a deeper valve. Ensure that the wellhead backpressure is not excessive or that the fluid used to kill the well for workover was not excessively heavy for the design.

Valve hung open.

Valve spacing too wide.

Try rocking the well when it will not unload. This will sometimes allow working down to lower valves. If a high-pressure gas well is nearby, using the pressure from it may allow unloading. If the problem is severe, the only solution may be to replace the current valve spacing, install a packoff gas-lift valve, or shoot an orifice into the tubing to achieve a new point of operation.

Continuous-Flow Wells

Unloading a well typically requires more gas volume than producing a well. As a result the input gas volume can be reduced once the point of operation has been reached. Excess gas usage can be expensive in terms of compression costs; therefore, it is advantageous, in continuous-low installations, to achieve maximum luid production with a minimum amount of input gas. This can be accomplished by starting the well on a relatively small input choke size, at 1/64 increments, until the maximum luid rate is achieved.

Intermittent-Flow Wells

In intermittent lift, the cycle frequency is typically controlled by an intermitter.

|

Fig. 3: Typical Intermittent-Flow

Gas

Well Operation

|

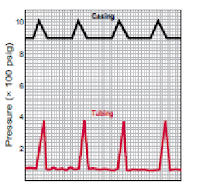

The cyclic operation of the injection gas causes the surface casing pressure to luctuate between an opening casing pressure (high) and a closing casing pressure (low). The difference in the surface opening and closing pressures during a single cycle is referred to as “spread.” Injection-gas volume per cycle increases as spread value increases.

To accomplish this, the initial injection-gas volume and the number of injection cycles must be more than required. A good rule of thumb is to set the cycle based on 2 minutes per 1,000 ft of lift, with the duration of gas injection based on 1/2 minute per 1,000 ft of lift. Reduce the number of cycles per day until the most luid is obtained with the least number of cycles, and then decrease the injection time until the optimal amount of lequid production is maintained with the least injection time. If one barrel or less is produced per cycle, the cycle time should probably be increased. Be sure the intermitter stays open long enough to fully open the gas-lift valve.

This will be indicated by a sharp drop in casing pressure. When a two-pen recorder is used, it will give a saw-tooth shape to the casing pressure line

Troubleshooting: Diagnostic Tools

Calculations

|

Fig. 4: Intermittent Gas Lift:

Saw-Tooth

Shape to Surface Casing Pressure

|

One method of checking gas-lift performance is by calculating the “tubing load required” (TLR) pressures for each valve. This can be accomplished by calculating surface closing pressures or by comparing the valve opening pressures with the opening forces that exist at each valve downhole based on the operating tubing, and casing pressures, temperatures, etc. Although this method may not be as accurate as a lowing pressure survey because of inaccuracies in the data used, it can still be a valuable tool in highgrading the well selection for more expensive diagnostic methods. Weatherford’s VALCAL gas-lift design software is available for this type of diagnostics.

Well-Sounding Devices

The luid level in the annulus of a gas-lift well will sometimes give an indication of the depth of lift. This method involves imploding or exploding a gas charge at the surface and uses the principle of sound waves to determine the depth of the luid level in the annulus. Acoustic devices are fairly economical compared to lowing-pressure surveys.

It should be noted that for wells with packers, it is possible for the well to have lifted down to a deeper valve while unloading, then return to operation at a valve up the hole. The resulting luid level in the annulus will be below the actual point of operation.

Tagging Fluid Level

Tagging the luid level in a well with wireline tools can sometimes give an estimation of the operating valve subject to several limitations. Fluid feed-in will often raise the luid level before the wireline tools can be deployed down the hole. In addition, luid fallback will always occur after the lift gas has been shut off. Both of these factors will cause the observed luid level to be above the operating valve. Care should be taken to ensure that the input gas valve was closed before closing the wing valve, or the gas pressure will drive the luid back down the hole and below the point of operation. This is certainly a questionable method.

Two-Pen Recorder Charts

To calculate the operating valve, it is necessary to have accurate tubing and casing pressure data. Two-pen recorder charts give a continuous recording of these pressures and can be quite useful if accompanied by an accurate well test. The two-pen recorder charts can be used to optimize surface controls, locate surface problems, and identify downhole problems.

Flowing Pressure Survey

In this type of survey, an electronic pressure gauge or bomb is run in the well under lowing conditions. These recording instruments can also measure temperature, and both ambient and “quick-response” models are available.

Under lowing conditions, a no-blow tool is run with the tools, which prevents the tools from being blown up the hole.

The no-blow tool is equipped with dogs, or slips, that are activated by sudden movements up the hole. The bomb is stopped at each gas-lift valve for a period of time, recording the pressures at each valve. From this information, the exact point of operation can be determined, as well as the actual lowing bottomhole pressure (BHP). This type of survey is the most accurate way to determine the performance of a gas-lift well, provided that an accurate well test is run in conjunction with the survey. The following procedure explains the process in detail.

Procedure for Running a Flowing BHP Test When the Well Is Equipped with Gas-Lift Valves

Intermittent-Flow Wells

Where to Install a Two-Pen Recorder

Connect Casing Pen Line

• At the well, not at compressor or gas distribution header.

• Downstream of input choke so that the true surface casing pressure is recorded.

Connect Tubing Pen Line

• At the well, not the battery, separator, or production header.

• Upstream of choke body or other restrictions. Even with no choke bean, a less-than-full opening is found in most chokes.

Comments