Porosity of Petroleum Reservoir Rocks

Porosity of Petroleum Reservoir Rocks

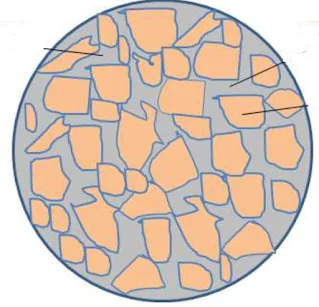

Sedimentary rock consists of grains of solid matter with varying shapes that are more or less cemented and between which there is empty space (Figure 2.1). It is these empty spaces that are able to contain fluids such as water or liquid or gaseous hydrocarbons and allow them to circulate.

|

Figure 2.1 Porosity |

where ф is porosity, Vp is

pore volume [cm3] and Vb -is total (bulk) volume [cm3].

Alternatively, we can subtract the

matrix volume (in this case, the ice cubes) from the total volume and divide it

by the total volume to obtain the porosity, as shown in the following equation:

where Vg is the matrix volume (grain volume) [cm3].

Overall, we can say that:

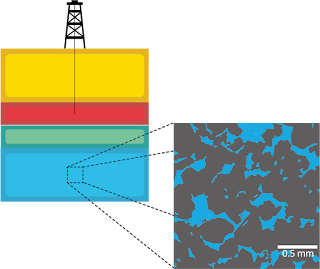

Reservoir rocks are porous and

contain fluids in their pores, as shown in Figure 2.2. Porosity

measurement from a core is part of routine core analysis RCAL. When we use the

term "core," we usually refer to a cylindrical rock sample with a

width and length of a few centimetres.

In addition, when dealing with rocks, we often refer to the matrix volume as the grain volume (Vg) and the total volume as the bulk volume (Vb). Note that the fractional porosity value is often multiplied by 100 to make it a percentage; however, it should always be a fraction when used in calculations. The porosity of reservoir rocks usually ranges from 5% to 40%. Table 2.1 shows typical porosity values for different reservoir rocks. The porosity of rocks within a reservoir indicates how much oil and/or gas is stored in that reservoir. Therefore, finding the porosity of the reservoir beforehand is important for engineers because it helps them estimate how economically viable that reservoir is and how many resources should be invested in it.

|

Table 2.1: Typical porosity values in reservoir rocks. |

|

|

Rock Type |

Range |

|

Loosely consolidated sands |

35–40% |

|

Sandstones |

20–35% |

|

Well-cemented sandstones |

15–20% |

|

Limestones |

5–20% |

Classification of Porosity

Porosity has two types of classifications: geological and

engineering.

Geological Classification of Porosity

In terms of geological classification, porosity is classified into

two subdivisions: primary and secondary. Primary porosity is the

original porosity that develops during the deposition of the material. Primary

porosity can be either intergranular or intragranular (Figure 2.3).

Intergranular porosity is the porosity between grains, while intragranular

porosity is the porosity within the grain itself. Intergranular porosity forms

the majority of the porosity of the rock. Secondary (induced) porosity

is developed after deposition by geological processes which result in vugs and

fractures.

|

Figure 2.3: Schematic showing the

difference between intergranular and intragranular porosities. |

Engineering Classification of Porosity

In terms of engineering

classification, porosity can be subdivided into two categories: total

and effective. Total porosity (фt) is the total pore volume

of the rock divided by the bulk volume. On the other hand, effective porosity

(фe) is the interconnected pore volume divided by the bulk volume.

Ineffective porosity is the isolated pore volume divided by the bulk volume. Figure

2.4 shows the difference between effective and ineffective porosity.

Usually in sandstones, фt = фe as they are relatively

homogeneous rocks. Carbonate and dolomite rocks, on the other hand, usually

have фt > фe since carbonates are typically

heterogeneous. As petroleum engineers we are mainly interested in the effective

porosity since hydrocarbons can only flow through connected pores.

|

Figure 2.4: Schematic showing the

difference between porosity subdivisions: total, effective, and ineffective. |

Calculation of Porosity

If we consider a cubic packing of

spheres (ideal situation) and look at a cube section as shown in Figure

2.5, the length of the cube is 2r, where r is the radius of the sphere.

Thus, the bulk volume of the cube will be:

Vb = (2r)3 = 8r3

The matrix volume in this case is

represented by the volume of the spherical portions in this cubic segment. We

have eight equal portions of one-eighth of a sphere in this cube, thus:

The porosity then becomes:

∅=(Vb-Vg)/Vb =1-π/6=0.476

We can conclude that the grain size

does not affect the porosity of the rock (as all the radii in the equation

cancel out). In other words, having large spheres or small spheres will lead to

the same porosity as long as they are all of the same size and have the same

packing (Figure 2.6). A value of 0.476 is the highest achievable

porosity, and naturally you will always come across a porosity value less than

this.

|

Figure 2.5: Schematic showing (a) a

cubic packing of spheres from which (b) a subset cube is selected and then (c)

analyzed. |

|

Figure 2.6: Schematic showing (a)

the large particle size and (b) the small particle size. Both have the same

porosity as the particle size does not affect the porosity value. |

Factors Affecting Porosity

Porosity can be affected by either primary or secondary factors.

Primary Factors

Particle Packing

Different packing arrangements lead to different porosities, as shown in Figure 2.7. A cubic packing of matrix (Figure 2.7a) leads to a highest possible porosity of 47.6%, as discussed previously, while rhombohedral packing of spheres (Figure 2.7b) leads to a highest possible porosity of 26.0%, which is lower than the previous case.

|

Figure 2.7: Different packing leads

to different porosities; (a) cubic packing has 47.6% porosity and (b)

rhombohedral packing has 26.0% porosity. |

Sorting

Particles are referred to as “well

sorted” when they are all of the same size while they are poorly sorted when they

are of different sizes (Figure 2.8). Well-sorted particles result

in a higher porosity compared to poorly sorted particles.

Secondary Factors

Cementing materials

The presence of more cementing

materials means less porosity as there is less void space available for the

storage of hydrocarbons.

Overburden pressure (compaction)

Overburden pressure will lower the

pore volume of the rock, leading to lower porosity.

Vugs, dissolution, and fractures

These are formed after deposition

and will increase the porosity of rocks. Dissolution is when the minerals

dissolve over time. Some minerals will dissolve in water. Vugs are large pores

formed by dissolution. Fracture is a break or separation in a rock formation.

Laboratory Measurements

There are usually two methods of

measuring porosity. We either measure it using laboratory measurements (RCAL)

at the centimeter scale or using wireline logging at the meter scale.

There are several methods of finding

porosity in the laboratory. However, we will focus on the two most common

techniques, which are the fluid displacement and gas expansion using a gas

porosimeter. All the rocks used in the laboratory core analysis are rocks

extracted from a reservoir using coring performed by a downhole instrument, as

shown in Figure 2.9.

|

Figure 2.9: Schematic showing a

downhole instrument used to collect rock samples from the reservoir (sidewall

coring tool). |

Fluid Displacement

The concept of fluid displacement is

based on mass/material balance. In this technique, we weigh a dry core and

measure the dimensions, specifically the diameter and length of the core. Then,

we vacuum saturate the core with water or brine (salt water), for instance, to

make sure that the water has filled all the pore spaces and no air is trapped

in the core (Figure 2.10). The core is then weighed to find the

saturated weight. Subtracting the saturated weight from the dry weight, we

obtain the weight of the water in the pore spaces (Figure 2.11).

By dividing the weight of the water by the density of the water, we obtain the

pore volume:

where Ws is the weight of

the core saturated with fluid [g], Wd is the dry weight of the core

[g], and ρ is the density of the fluid [g/cm3]; since the fluid in

this case is water, the density is 1 g/cm3.

From the displacement method, we can

also find the bulk volume of irregular shapes. Let us consider a rock with an

irregular shape as shown in Figure 2.12. In order to measure the

volume, we need to coat the surface of the rock with an insulating material

such as paraffin (ρ = 0.9 g/cm3) to prevent the fluid we are using

to enter the pores. However, before that we need to measure the dry weight of

the rock sample and the weight of the core with the paraffin. The difference

between the two weights divided by the density of paraffin is the volume of the

added paraffin. This volume will then be subtracted from the final volume

calculation. After performing all these steps, we can find the volume of the

rock using two methods:

1.

We

can record the initial volume of water in the graduated cylinder, and then

record the new volume of water after submerging the rock. The difference

between the new volume and the initial volume is the volume of the rock.

However, we also need to subtract the volume of the paraffin to obtain the

actual bulk volume of the rock (Figure 2.12a).

2.

We

can also use the Archimedes’ principle to find the bulk volume of the rock (Figure

2.12b):

Wdf =

Wr − Wa

where Wdf is the weight

of the displaced fluid [g], Wr is the dry weight of the core or the

weight of the core at the initial conditions before submerging (real weight)

[g], and Wa is the weight of the core after submerging it in the

fluid (apparent weight) [g]. Wa is less than the real weight due to

buoyancy forces. Note that we need to suspend the core in order for buoyancy

forces to act on the core. Finally, in order to measure the bulk volume, we

need to use the following equation:

where ρ is the density of the fluid

in which the core is submerged [g/cm3], which in this case is water,

and Vcoat is the volume of coat used, usually paraffin [cm3].

Note that Vcoat can be measured by subtracting the weight of the

sample with the coat from the weight of the sample without the coat and divide

the product by the density of coat used, i.e., paraffin.

The Gas Expansion Method

The second method used to measure

porosity is the method of gas expansion using a helium porosimeter, which

relies on Boyle’s law:

P1V1

= P2V2 )

In this method, we usually use

helium as it has a low molecular weight and so can easily enter the smallest

pore spaces, which will lead to the most accurate results. We use the system

shown in Figure 2.13a which consists of two chambers separated by

a valve, with a pressure sensor in the first chamber. Chambers 1 and 2 should

be of fixed volumes. To break down the process, we need to understand the

following:

We fill chamber 1 with helium and

then record the pressure; thus, we have P1 and V1 as shown in Figure 2.13b.

If we open the valve to chamber 2,

as shown in Figure 2.13c, then Boyle’s law becomes:

P1V1

= P2(V1 + V2) )

If we consider an actual case where

we have a rock inside chamber 2 (Figure 2.13d), then Boyle’s law

becomes:

P1V1

= P2(V1 + V2−Vm) )

In this case, helium will access all

the chambers and the pore spaces. The only space helium will not access is the

matrix volume as it is not porous; using this technique, we can calculate the

porosity.

We will calculate Vm from

the equation above, as V1 and V2 are constants and P1

and P2 will be read from the equipment. After finding Vm

and also knowing the bulk volume of the core, which is easy to measure, we can

calculate the pore volume as Vp= Vb – Vm and

the porosity is equal to Vp divided by Vb.

It is important to mention that both

the fluid displacement and gas expansion tests measure the effective porosity

as fluids can only access the connected pores.

Measurement of grain volume is

easily completed using a type of Boyle's law apparatus illustrated in Figure.2-13,

where a clean, dry sample is placed in a chamber of known volume. This chamber

is isolated from the upstream pressure chamber, which is also of known volume.

The upstream pressure chamber is charged to a pressure of approximately 100-psi

and then isolated. The connection between the pressure chamber and sample chamber

is opened, and gas expands into the sample chamber, causing a drop in the

original reference pressure.

If the volumes of the pressure and

sample chamber are known, the grain volume may be calculated using the measured

pressure.

Where V1

-reference cell volume, V2 -sample cell volume, Vg -grain

volume of sample, P1 -initial pressure in reference cell, and P2 -final pressure

in system

Further, the cell volumes Vc

and VR are difficult to measure with the desired accuracy. This

instrument is, however, easily calibrated with precisely known solid volumes

such as steel balls. If all measurements are then started at the same P1,

it is a simple matter to obtain Vs from a previously determined

calibration plot of Vs vs P2.

Grain volume may also be calculated

from

Equation (-) is often used with the

typical value for

Grain/Matrix Density

Grain/matrix density [g/cm3]

is also considered a part of the RCAL. In order to measure it, we need to know

the bulk volume, the weight of the rock sample, and the pore volume. Finding

the matrix density can easily be a part of porosity measurement as only the

weight of the sample will be required. After we measure the porosity, we can

find the matrix volume and hence the matrix density can be obtained through the

following equation:

where ρg is the density

of the matrix [g/cm3], Wd is the weight of the matrix or

the dry weight of the core [g] as the density of air is assumed to be

negligible; Wg = Wd (dry weight of the entire core), and

Vg is the volume of the matrix [cm3], which is the bulk

volume minus the pore volume (Vb – Vp).

Typical matrix densities of

different rock types are shown in Table 2.3.

|

Table 2.3:

Typical matrix densities for different rock types. |

|

|

Lithology |

ρm [g/cm3] |

|

Sandstone |

2.65 |

|

Limestone |

2.71 |

|

Dolomite |

2.87 |

The Russell method utilizes an

especially designed volumeter (Figure. 2-10), and the bulk volume

and grain volume are determined volumetrically. The porosity determined is total

porosity.

|

Figure. 2-10 Russell volumeter for

determining grain and bulk volumes of

|

rock samples. |

Consider a bulk volume of rock with

a surface area of one acre and a thickness of one foot. An acre-foot is the

basic rock volume measurement used in oil field calculations. It is also

standard practice to express all liquid volumes in terms of barrels. The

following conversion factors are useful:

acre

= 43,560 ft2= 4,047 m2

1

acre-ft= 43,560 ft3 = 4,047 m2

1

bbl = 42 gallon=5.61 ft3 = 0.159

1

acre-ft = 43560/5.61 = 7758 bbl

Consider a reservoir with an area of

A acres and an average thickness of h feet. The total bulk volume of the

reservoir can be determined from the following expressions:

or

where A is surface area of

reservoir, [acres], and H is average thickness of formation, [feet]

then it is obvious that the pore

space within a rock is equal to

The reservoir pore volume in cubic

feet

The reservoir pore volume in barrels:

as showing by Figure.2-13

the volumetric equation of oil in place

Where N- Stock-tank oil in place, [bbl/acre-ft],

So - fraction of pore space occupied by oil (the oil saturation), Sw

- the water saturation, and Bo - the formation volume factor for the

oil at the reservoir pressure, reservoir barrel/stock tank barrel, or bbl/STB.

It is necessary to determine Sw

some water will always exist within the reservoir rock and that its volume must

be subtracted from the space available for oil. This water is commonly called

connate water and is assumed to be incompressible in this equation.

It is assumed that the pore space

will be occupied by either oil or water, and that no free gas will be present.

Consequently, the equation as given must be applied to the reservoir at or

above the bubble point and is generally used to compute the initial oil in

place.

Averaging Porosity

The reservoir rock may generally

show large variations in porosity vertically but does not show very great

variations in porosity parallel to the bedding planes. In this case, the

arithmetic average porosity or the thickness-weighted average porosity is used

to describe the average reservoir porosity. A change in sedimentation or

depositional conditions, however, can cause the porosity in one portion of the

reservoir to be greatly different from that in another area. In such cases, the

area-weighted average or the volume-weighted average porosity is used to characterize

the average rock porosity. These averaging techniques are expressed

mathematically in the following forms:

Arithmetic average ∅=(∑▒∅i )/n

Thickness-weighted average ∅=(∑▒〖∅i×hi 〗)/hi

Areal-weighted average ∅=(∑▒〖∅i×Ai 〗)/Ai

Volumetric-weighted average ∅=(∑▒〖∅i×Ai×hi 〗)/〖Ai×hi〗

Where n -

total number of core samples, hi - thickness of

core sample i or reservoir area i,

This lecture was uploaded to YouTube after formatting it in PowerPoint format PPT as a presentation. The link to the lecture #2 is on our YouTube channel - Knowledge Fields Channel here.

Comments